Poultry farm ventilation Fans & Motors

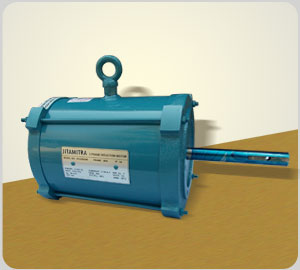

Shriram Coating has manufactured and tested the motor to a high standard of excellence. The motor confirms to it specification. The motor is efficient, easy to install and simple to maintain with trouble free service. The application of the motor is in poultry farm to maintain the temperature inside the shed.

Enquire Now

| OUTLINE DIMENSION - POULTRY FAN MOTOR |

|

Motor Description

|

||||||||||||

| SINGLE PHASE | THREE PHASE | |

| FRAME | 56 | 56 & 90L |

| OUTPUT (kW / HP) | 0.74 / 1 | 0.74 / 1 & 1.1 / 1.5 |

| VOLTAGE (V) | 225 ± 6% | 415 ± 6% |

| RPM | 880 | 880/1370 |

| EFFICIENCY % | 70 | 65/73 |

| INSULATION CLASS | F | F |

| DUTY | S1 | S1 |

SPECIFICATIONS: MECHANICAL

| ID | TYPE | SPECIFICATION |

| 1 | MOTOR WEIGHT | 13.650 Kg |

| 2 | FRAME | B56 |

| 3 | SHAFT LENGTH | 105.3 ± 0.1 mm |

| 4 | CENTRE HEIGHT | 80 ± 0.1 mm |

| 5 | KEYWAY LENGTH | 39.800 to 40.200 mm |

| 6. | KEYWAY WIDTH | 4.970 to 5.000 mm |

| 7. | KEYWAY DEPTH | 2.8 to 3.0 mm |

| 8. | STATOR OD | 144.0 ± 0.1 mm |

| 9. | GRILL FITMENT HOLE | Ф6.5 100 PCD mm |

FAN WITH POLYPROPELENE BLADE SIZE 36 INCH

|

|

These motors are sound in design and robust in construction with reliable and satisfactory working condition with proper inputs.

The motor is efficient, easy to install and simple to maintain with trouble free service. However it will give you good service for a long time when properly installed and operated with normal care and maintenance.

Electric connection: electric connection should be carried out by an authorised electrician. Ensure phase voltage 5 before starting the motor.

Freeness: Ensure the rotating are free before switching on the supply.

Direction of rotation: Check the direction of rotation, it should be clockwise (viewing from shaft side) for correct air flow. If the air flow is not correct interchange any two phase connection.

Replace the old grease in the bearing once in 6 months. Always use Balmer Lawre make high Tech EP-2 grease or equivalent.